INTRODUCTION

1.Virtual water is the water ‘embodied’ in a product, not in realefficient water use.

2.Making the link between consumption patterns and the impacts on water.

3.sense, but in virtual sense, It refers to the water needed for the production of a product.

4.Virtual water trade as an instrument to achieve water security.

OBJECTIVES

1.To estimate the virtual water footprint of Giant Freshwater Prawn in Bangladesh;

2.To compare the water use efficiency among various production methods through the virtual water footprint;

3.To identify the contribution of virtual water trade from Khulna region;

4.To show the percentage of virtual water trade outflows from the Bangladesh; and

5.To recommend a policy framework for the virtual water trade of fresh water prawn to enter the world trade industry;

METHODOLOGY

MAP

METHOD OF CALCULATION

Calculation of virtual water content of fresh water prawn

VWFP [Processed, p.c.] = [(VWCPL15 ×Pf(N)) + NWU] ×Pf(P) + PWU + DWU + PrWU

VWFP [Processed, p.c.] denotes the virtual water footprint of per capita processed prawn and Pf is the product fraction of the respective stage.

Product fraction (Pf) can be calculated as

Pf = No. of Individual/survivility

Calculation of virtual water content of PL15

VWCPL15 = HWU/Ply

VWCPL15 denotes the virtual water content of PL15. HWU and Ply is the water used in the hatchery and post-larvae yield

Water used in the hatchery (HWU) was calculated as..

HWU = WUST + WULCT + WULRT

Here,

WUST = water used in the spawning tank

WULCT = water used in the larvae collection tank

WULRT = water used in the larvae rearing tank

The WUST and WULRT were calculated as follows

WUST = b1 + b2 + b3 + b4 + b5

Where, WUST = water used in the spawning tank;

b1 = water required to transport broodstock from field to hatchery;

b2 = water used to give rest the broodstock;

b3 = water volume of the spawning tank;

WULRT = V1-20 + WC1 + V21-45 + WC2 + fa + fc

Where,

WULRT = total water used in the larvae rearing tank;

V1-20 = water volume of the LRT in the first 20 days;

WC1 = amount of water changed in the first 20 days;

V21-45 = water volume of LRT in the next 25 days;

WC2 = amount of water changed in the next 25 days;

fa & fc = virtual water added due to Artemia and custard which was used as feed

Water used in the Nursery and Growout pond were calculated by the following equations:

NWU = Vw + tr + P + fw

NWU denotes the total amount of water used in the nursery culture, Vw, tr, P and fw the water volume of the nursery pond, water used to carry post larvae, amount of precipitation and virtual water added due to food respectively

PWU = Vp + tr + WCp + P + fw

Here,

PWU = water used in the growout pond

VP = water volume of the growout pond

tr = water used to transport fry from nursery to pond

WCP = water changed during the pond culture

P = water added due to precipitation

fw = water added due to feed

RESULT AND DISCUSSIONS

Water Usage in Different Stages of Prawn Production

Hatchery

Nursery

Growout pond

Depot

Processing Industry

Water utilization in the hatchery to produce post larvae (PL15)

Water utilization in the natural pond culture to produce giant fresh water prawn

Water utilization scenario of three pond culture system

DEPOT

water required in depot for per capita prawn of 100 gm is 0.1 liter, for 80 gm it is 0.083 liter and for 50 gm of giant fresh water prawn is only 0.05 liter

Processing industry

About 66.35 liter water is used to process one kilogram prawn or shrimp. And if we calculate the water used to processed per capita prawn then it is 6.635 liter for prawn of 100 gm (produced from natural culture system), 5.53 liter for prawn of 80 gm (produced from extensive culture system) and 3.32 liter for prawn of 50 gm (produced from improve extensive culture system).

Virtual water content of giant fresh water prawn produced from natural system

Virtual water content of processed fresh water prawn produced from extensive culture system

Virtual water content of prawn produced from improve-extensive culture system

Comparison between virtual water content of fresh water prawn produced from three culture system

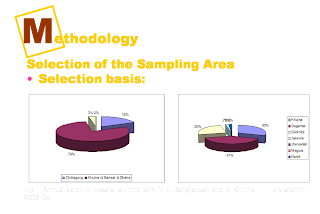

Virtual water trade from Khulna region

Export of Virtual Water from Bangladesh as a Result of Shrimp Trade

CONCLUSION

Water is increasingly becomes a scarce resource and it should therefore be valued as such. It is said that water should be allocated to where it produces the greatest benefits. In fresh water prawn production, a huge amount of water is used in every stage of its life cycles and also its final processed products. A bridge has to be built between water management practice and economic thinking in this research. In allocating and using water in an efficient way, there are different levels of decision-making:

Local water use efficiency

Water allocation efficiency

Global water use efficiency

The climatic condition of our country favors shrimp farming, earning a lot of foreign exchange every year due to export of processed shrimp. As shrimp aquaculture also caused significant environmental damage, it needs to consider the value of virtual water of its export products. Because presently the country only get the value of the product of processed shrimp, not the value of virtual water in the world market